Shop SMS SMS Technical SMS products & services SMS in articles and webinars Testimonies

SMS and the environment SMS news Interesting links SMS: How, why and when SMS Q&A

SMS for design and

advertising Getting started with SMS colours SMS BLOCKS Cost of ownership |

SMS for print Printers (in all categories) SMS READY - or not? |

SMS technical details

SMS colours are hand picked colours from the CMYK colour gamut for printing

on bright, white paper in accordance with the international standard ISO

12647-2-2013. The colours are derived from CIELAB but delivered to

the end user in CMYK.

Each SMS colour is adapted to look identical

colourwise when printed on coated and uncoated paper, which again

means that the CMYK composition of the SMS colour for coated paper is

never the same as it is for uncoated paper.

SMS colours are made from the ground up be achieved in 4 colour (CMYK) printing for newspapers, magazines, business cards, posters etc. etc., analog (offset, gravure, flexo) or digital.

SMS colours can be:

Hard proofed (printed proof) and certified according to ISO 12647-7-2016 (master proof).

Viewed correctly on monitor - for professional softproofing of CMYK version during design and layout.

Viewed correctly online on native sRGB monitors and smart devices - in their sRGB version (P20, P20e, P20x).

Viewed correctly on Television (Rec. 709 RGB) in their REC. 709 version

(P20, P20e, P20x).

You can actually make good SMS colour decisions on your smartphone and it

is safe for designers to present their SMS designs to customers online

for approval as a first step. If the colours look right online, they will

look right in print as well.

For advertising campaigns this should be enough approval in general.

However, if you are developing a new brand, that is supposed to be used in the coming years, we recommend the final decision to be made based on our certified colour proofs in normal daylight. In this case you can of course get your initial OK from the brand owner on his smart device (sRGB) - i.e. if he or she approves of the artwork and the colour combination.

The ISO certified paper proof is however the master, while softproofing on your monitor, viewing the colour on a website and smart devices and on Television is where we immitate the printed master - and obviously we cannot control the state of random monitors, smart devices and Television sets, although if they are not too old, the should be close to the final SMS colours.

Papertypes and printing standards:

There are two factors that determine the final outcome of colours and we need to know both before we issue a CMYK version of an SMS colour for printing.

1) The paper / substrate type

If you are preparing a job, you need to select the paper or substrate you want your job printed on. Don't leave it to your Printer to "pick something good". The white point of the chosen paper/substrate affects your colours.

Here, again it is easiest to stick to the standards.

Printing on coated paper / smooth/closed surface.

If you want to print on smooth and mostly closed surface, for instance

coated paper, check with your supplier if the paper/substrate has a

white point in accordance with Fogra 39 or Fogra 51. The difference is

that paper that is correct according to Fogra 39 is slightly more

neutral than paper that is correct according to Fogra 51.

You might also say that the substrate that has the correct white point

according to Fogra 51 is "brighter".

In fact it is slightly more bluish/colder, when you look at it in

daylight - which in most circumstances will make your colours slightly

cooler.

NOTE: Regretably many paper manufacturers have not yet updated their spec sheets from M0 to M1 and thus the white point values given are not correct according to the current ISO 12647-2-2013 standard, which SMS is based on.

If you measure the paper yourself, for Fogra 39 compliant substrate, the LAB value should be approx. 94, 3, -3 when you measure with the condition M1 (D50/2°).

M1 means that your instrument measures the white point of your paper,

including the part of the spectrum that

so-called optical brighteners affect. Optical brighteners are

commonly added to make the paper/material/substrate seem brighter.

The older M0 standard does not pick those brighteners up and

consequently M0 instruments don't actually "see" the actual colour of the

paper, - the same way your eyes do, unless you only look at your job

under an old 40w lamp in your living room, which is typically not the

target - again although there may be exceptions, for instance if your

job will be displayed in a museum.

For Fogra 51 compliant substrate, the M1 LAB value should be approx. 95, 2, -6.

Printing on uncoated paper/absorbant substrate

If you plan to print your job on uncoated paper/ink absorbant substrate, check with your paper supplier if the paper has a white point according to Fogra 47 or Fogra 52. The same applies. The Fogra 52 paper is brighter/more bluish than the Fogra 47 compliant paper.

The white point appropriate for Fogra 47 compliant paper is the same as for Fogra 39, - approx. 95, 2, -6 (M1) while the Fogra 52 compliant white point is approx. 93, 3, -10.

If you have an instrument that can measure both with the M1 and M2 condition, the difference in the *b value is in fact the proportion of OBA in the paper. M2 blocks the part of the spectrum that is affected by UV, which is exactly what triggers those OBA's in the paper. In normal daylight, there is some UV (Ultra Violet) light and thus paper and any material that contains OBA seems to be "cooler".

If you happen to be of the disko generation you are no doubt familiar with the effect of so-called "black light if you walk into the disco in a white shirt. It seems to glow - but it's actually just the optical brighteners in the shirt that get excited and start glowing when you shed UV light on them.

The Spot Matching System is based at it's origin on the white points of current Fogra 51 and Fogra 52. We assume that most customers will prefer brighter paper since that has been the trend from the dawn of time.

However we offer customers to adapt their SMS colours to the more neutral Fogra 39 and Fogra 47.

2) The print standard of your Printer

The second part of the equation that you need to be on top of is the CMYK printing standard of your Printer.

We use the same standards here, - i.e. Fogra 39 or Fogra 51 for coated paper and Fogra 47 or Fogra 52 for uncoated paper.

You may find yourself in a situation where the paper you picked is correct according to Fogra 51 while your Printer tells you that their print standard is Fogra 39. This is quite common actually. So is picking paper that is Fogra 52 compliant while your Printer needs a Fogra 47 compliant PDF file for his output.

This is a problem if you deliver your files in CMYK format and the only way to handle this is to use the icc profile that is appropriate according to the print standard of your Printer - in this case Fogra 39.

The reason for this is that when the new ISO standard, - ISO 12647-2-2013 was created, unfortunately the assumed dot gain / tonal value increase for the printing presses was changed compared to the old standard. So if you were to use the new icc profile PSO Coated v3 (which applies to Fogra 51 print condition and substrate) and your Printer would output it with his Fogra 39 output curves, you would not get anything like what you saw on your monitor.

Dot gain or Tonal Value Increase (TVI) is basically how much each dot in your file increases when the ink is pressed onto the paper during analog printing. For example if you have a 50% halftone in your file, you might expect the outcome from press to be approx. 65% on coated paper - but again, not the same between the old ISO standard and the new one.

You should thus in this case use the icc profile ISO Coated v2 / ISO Coated 300 v2.

The outcome will be that the final print will be slightly cooler than what you saw on your monitor - and the proof (which will probably be according to the old ISO 12647-2-2004 standard) would look warmer / more yellow than your printed job, when you compare it in daylight.

So, if you are anything like me and you don't like not knowing what to expect; if you want to keep your bright paper, look for a Printer that can print according to the new standard, - or pick paper that is closer to the white point of the old Fogra 39 standard for your job.

In the above case, if you insist on keeping your bright paper while your Printer insists on printing according to Fogra 39, you would order the following SKU for your SMS colours:

P10: SMS CMYK version for printing on coated paper (White point: Fogra 51, print standard Fogra 39)

This would at least make your SMS colours correct, even if everything else in your document would be too "cool", since we know your paper is bright white, while we adapt the colours to the final dot gain of your Printer for this papertype.

* * *

DeltaE2000 is the standard used in the current ISO 12647-2-2013 and

related standards to define colour difference.

A DeltaE2000 of 3 is considered "reasonable" and a DeltaE2000 of 2 or

less is usually considered very good where the colour difference is not

visible to the average person.

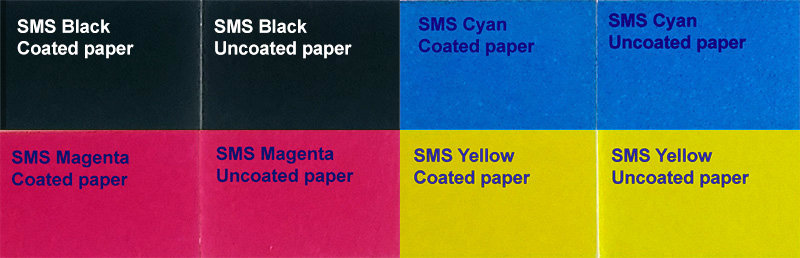

The measured avarage DE2000 between SMS CMYK colours printed on coated paper and the same colours printed on uncoated paper is less than 1, - which in other words means that the colour difference between SMS colours for coated paper and uncoated paper is not detectable by the human eye. The only thing that is different is that there is a slight reflection of the light in the case of the coated paper, while there is no reflection in the case of uncoated paper.

SMS primary colours. Coated and uncoated

paper. Composed photograph of our ISO certified (printed) proofs side by

side for printing in accordance with ISO 12647-2-2013.

SMS, 420 CMYK colours, difference between printing on coated and uncoated paper:

| Delta E-76 | Delta E2000 | |

| Average | 1,47 | 0,88 |

| Max | 4,13 | 2,21 |

For comparison the average DeltaE2000 of printed primary and secondary process (CMYK) colours according to the ISO 12647-2-2013 target values between coated paper (CD1 Premium Coated) and uncoated paper (CD5 Woodfree, uncoated) is over 8.

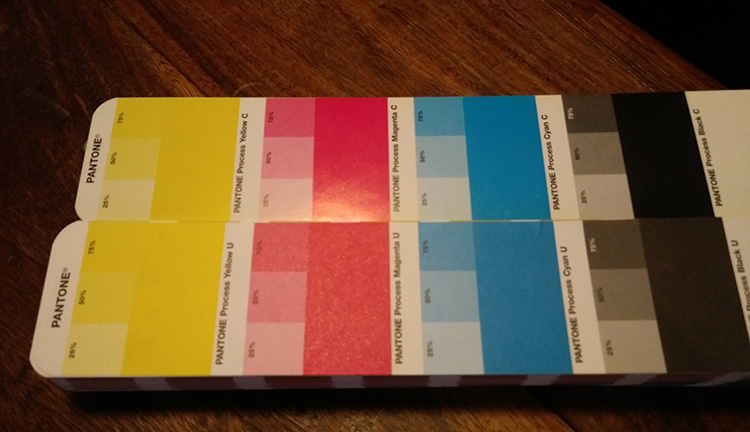

Normal process colours. Picture of coated and

uncoated CMYK colour guides from Pantone, printed in accordance with ISO

12647-2.

Standard CMYK colours, difference between printing on coated and uncoated paper:

| Delta E-76 | Delta E2000 | |

| Average | 19,63 | 8,37 |

| Max | 25,24 | 12,47 |

To put this into perspective:

If you use SMS Cyan as your colour for coated and uncoated paper, the measured DeltaE2000 between SMS Cyan C and SMS Cyan U is 1,42 according to our certified SMS proof.

If you use 100% process Cyan as you colour for printing on coated and uncoated paper, the DeltaE2000 should be 5,62.

If you use SMS Magenta you get a DeltaE2000 of 0,6 between the coated and uncoated version of the colour according to our certified proofs and our own measurements.

If you pick 100% process Magenta as your colour for both coated and uncoated paper, the DeltaE2000 will be approx. 8.

This gets really painful if you compare SMS Process black to standard process black (K).

If you use SMS process Black (K) as your colour (black is strictly speaking not defined as a colour) you get a DeltaE2000 difference of 1,43 between the coated and the uncoated version.

Use 100% standard K and you get a DeltaE2000 difference in colour between the coated and uncoated version of 12,47!

This is not a criticism on the ISO 12647-2-2013 standard and not at all

on my friends at Pantone LLC.

This is simply

because the same process inks are used for printing on coated and

uncoated paper, - same chronic syndrome, making the life of the designer

hard, that comes up again and again when the same inks are used for

printing on different substrates, which is discussed further

here.

If in doubt, the easiest way to see this for yourself is to look up the primary process inks in your Pantone CMYK guides and compare the coated and uncoated version, side by side.

So in conclusion, if you are planning to use both coated and uncoated paper for CMYK printing of your design, we recommend using our SMS colours, rather than fixed process variations.

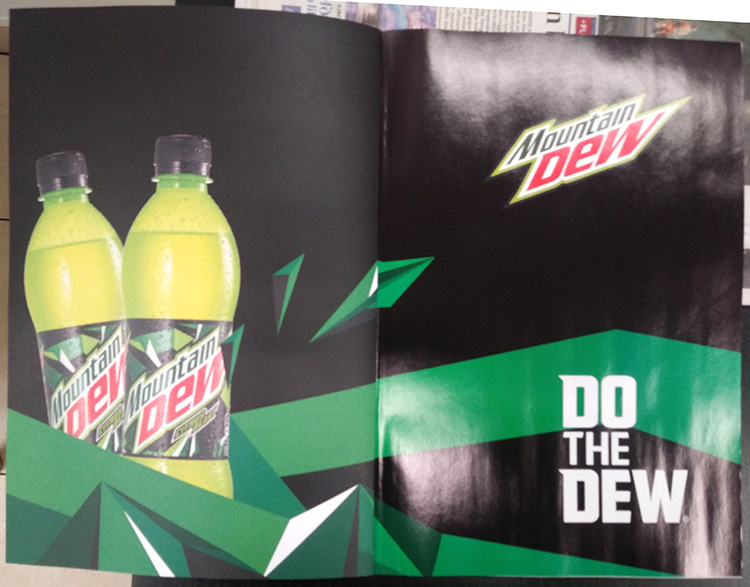

A spread from a random magazine. The cover

of the magazine is uncoated paper, the inside of the magazine gloss

coated paper.

-------------------------------------------------------------------------------------------------

Settings and job procedure where SMS colours are in use:

SMS colours are based on the ISO 12647-2-2013 standard for white coated (PS1) and uncoated paper (PS5).

Printshops in all categories need to be able to

receive and

output PDF documents set up for printing according to Fogra 51 for

coated paper and Fogra 52 for uncoated paper, in full accordance with

the current ISO 12647-2-2013 standard.

Printshops are obviously allowed,

at their own discretion, to convert the documents to an inhouse output

standard but the final print has to be in full accordance with this standard.

We are temporarily able to adjust our SMS colours to print correctly in accordance with the older ISO

12647-2-2004/AMD 2007 with output in accordance with Fogra 39 for coated

paper and Fogra 47 for uncoated paper, but this has to be made clear before

we deliver an SMS colour for production in CMYK.

To make sure your Printer is up to the task of printing SMS colours correctly, you need to ask your Printer the following question:

"Do you accept PDF master files prepared for printing according to:

a) Fogra 51 for printing on coated paper and Fogra 52 for printing on uncoated paper?

or

b) Fogra 39 for printing on coated paper and Fogra 47 for printing on uncoated paper?

If the answer is yes, they should be able to print any SMS colour you throw at them. It is a good idea to suggest to your Printer that they suscribe to SMS and familiarize themselves with the Spot Matching System colour palette.

We have prepared free test forms that we are happy to provide them with to check if they need to make adjustments in their workflow to be, what we call, SMS READY - see top of the page.

In general, Printers that are PSO certified (Process Standard Offset) by Fogra or Ugra as well as G7 Master Facilities certified by Idealliance should be a safe choice for printing SMS colours correctly.

Printers that are not certified might want to consider contacting one of the organizations

listed here above for assistance and advice. Getting your colours under

control is easier and less expensive than you probably imagine.

Printshops that are SMS subscribers, feel free to contact

sms@spot-nordic.com for advice.

Brand owners, Advertising Agencies/freelance designers and Printers may

subscribe to SMS right here on our site.

First read all about the advantages of subscribing to SMS -

here.

For consistent outcome from printing we recommend the use of "ordinary" bright

white paper for both coated and uncoated printing. If you are seeking an

off-white feeling for your job, we recommend that you simply print the

background within the layout.

That way you can keep your colours correct. This is nota bene true for

all colour printing and is not SMS specific.

When printing SMS colours in CMYK the general rule is that they are

resistant to varnishing and coatings (oil based, waterbased and UV

based) and lamination should in general not be a problem, since the

colours are printed with standard process inks.

Settings for CMYK printing:

SMS colours for CMYK printing are delivered as CMYK halftones, based on the output and papertype to be used. You need to make clear to your Printer that CMYK colours in your document should be printed as they are - i.e. they should not be converted by the Printer without checking with us first. This should not be a problem in most cases since typically only RGB colours within a document are converted to the destination CMYK output (and CMYK colours left as they are).

In order for us to be able to prepare a CMYK colour variant, strictly speaking all we need to know is the CMYK icc profile. If we only get the CMYK icc profile, we will assume that the white point and the type of paper as well as the print standard of your Printer is in accordance with that CMYK icc profile. If there is a twist - let's say if the white point of your chosen paper is closer to Fogra 51 but your Printer is printing according to Fogra 39, then you need to inform us of that when you order, otherwise the final colour will not be as close to perfection as we want it to be. In this scenario for instance the final colour will be slightly more bluish than the original SMS colour you picked if you simply order the Fogra 39 version of it.

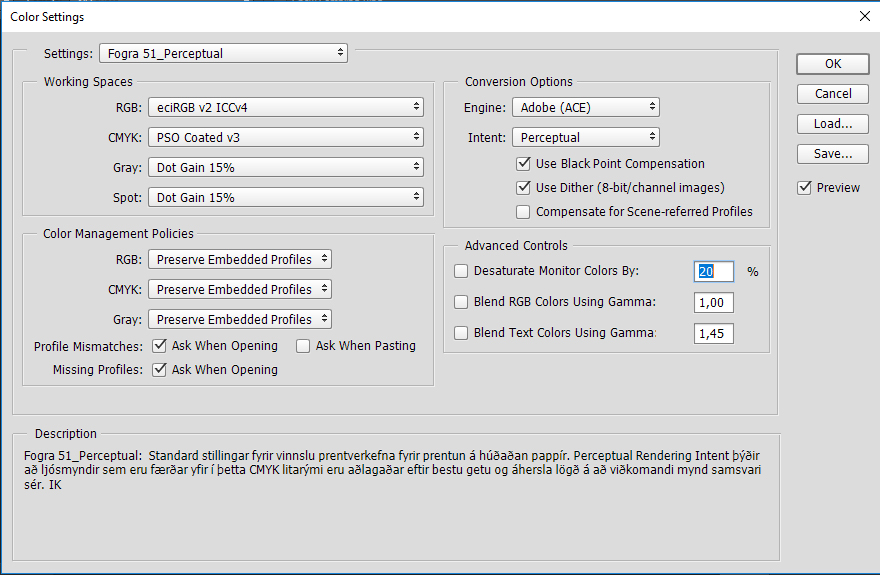

ISO 12647-2-2013: Fogra 51 (bright, white coated paper)

If you are preparing a job for CMYK printing on coated paper according to Fogra 51, order SMS colours acc. to Fogra 51 (P9).

For these purposes we recommend the following settings:

Relative colourimetric Rendering intent is also ok and if you prefer to use Adobe RGB, that is also fine.

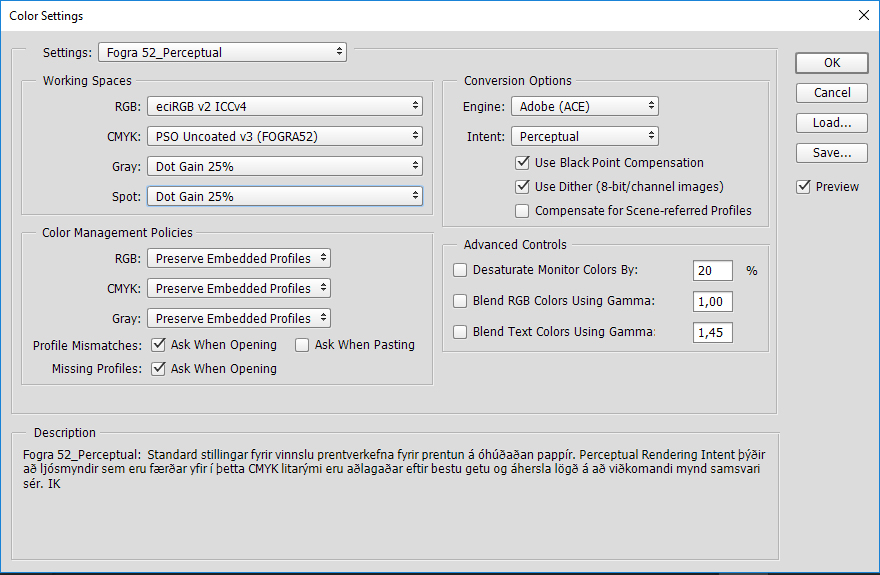

ISO 12647-2-2013: Fogra 52 (uncoated, bright, white paper)

If you are preparing a job for CMYK printing on uncoated paper according to Fogra 52, order SMS colours acc. to Fogra 52 (P11).

For these purposes we recommend the following settings:

Relative colourimetric Rendering intent is also ok and if you prefer to use Adobe RGB, that is also fine.

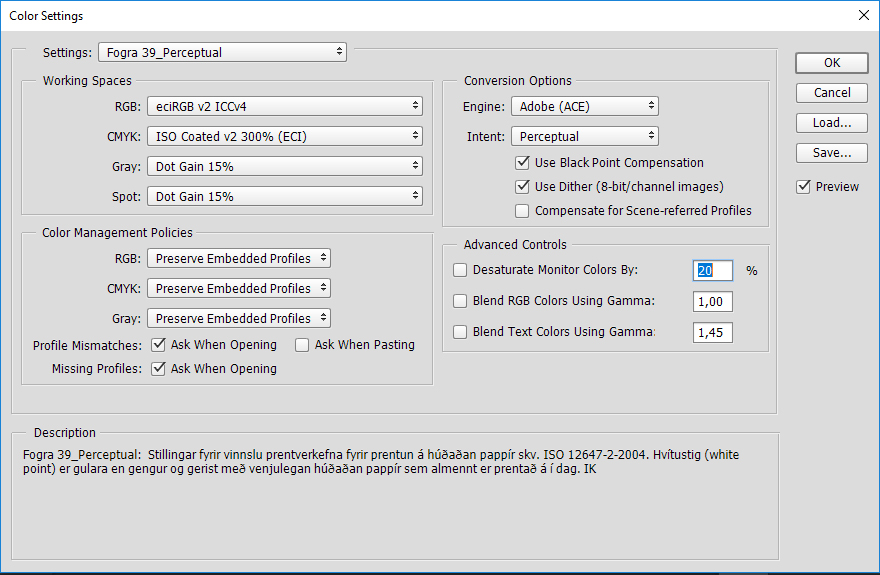

ISO 12647-2-2004/AMD 2007: Fogra 39 (coated paper)

If you are preparing a job for CMYK printing on coated paper according to Fogra 39, be sure to order SMS colours acc. to Fogra 39 (P10).

For these purposes we recommend the following settings:

Relative colourimetric Rendering intent is also ok and if you prefer to use Adobe RGB, that is also fine.

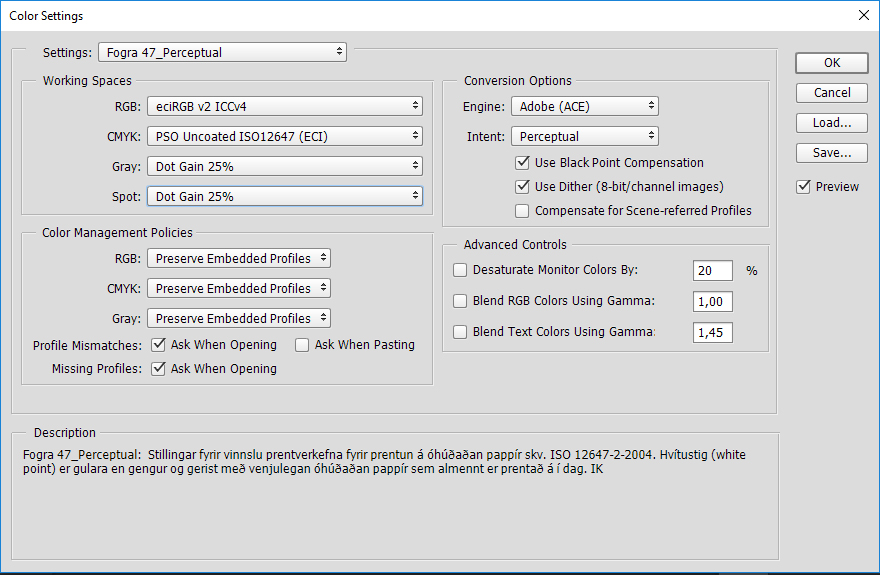

ISO 12647-2-2004/AMD 2007: Fogra 47 (uncoated paper)

If you are preparing a job for CMYK printing according to Fogra 47, make sure to order SMS colours acc. to Fogra 47 (P12).

For these purposes we recommend the following settings.

Relative colourimetric Rendering intent is also ok and if you prefer to

use Adobe RGB, that is also fine:

Please contact sms@spot-nordic.com if you have questions.

Shop SMS SMS Technical SMS products & services SMS in articles and webinars

SMS and the environment SMS news Interesting links SMS: How, why and when SMS Q&A

|

SMS for design and

advertising Getting started with SMS colours SMS BLOCKS |

SMS for print Printers (in all categories) SMS test forms |